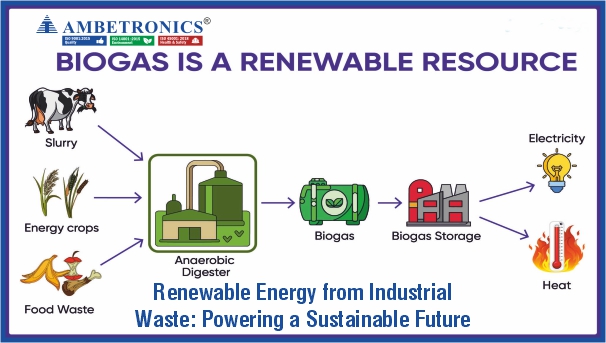

Renewable Energy from Industrial Waste: Powering a Sustainable Future

Renewable energy from industrial waste gases such as biogas is becoming a key pillar of sustainable industrial development. By converting organic and combustible waste into useful energy, industries can reduce environmental pollution, lower operating costs, comply with regulations, and significantly cut their carbon footprint.

Several sectors actively contribute to waste-to-energy generation. The sugar industry utilizes bagasse, molasses, and press mud, while distilleries and ethanol plants produce biogas from spent wash. Food processing units such as dairies and breweries generate biodegradable waste suitable for anaerobic digestion. The pulp and paper industry uses black liquor and sludge, and the textile and pharmaceutical industries convert organic effluents into renewable gas. Additionally, agriculture and dairy farms supply crop residues and manure, municipal solid waste plants process urban organic waste, and biomass and waste-to-energy plants utilize organic waste materials to generate biogas for power and heat applications.

However, these processes involve hazardous gases including methane (CH4), hydrogen sulphide (H2S), carbon monoxide (CO), hydrogen (H2), and oxygen (O2). Continuous gas monitoring is therefore essential to ensure worker safety, prevent explosions, optimize process efficiency, meet regulatory requirements, and protect equipment and infrastructure.

As manufacturers of gas analyzers and gas detectors, we provide advanced solutions for real-time gas monitoring, leak detection, biogas quality analysis, and system integration. Our technologies help renewable energy plants operate safely, efficiently, and reliably, enabling industries to maximize energy recovery while building a cleaner and more sustainable future.